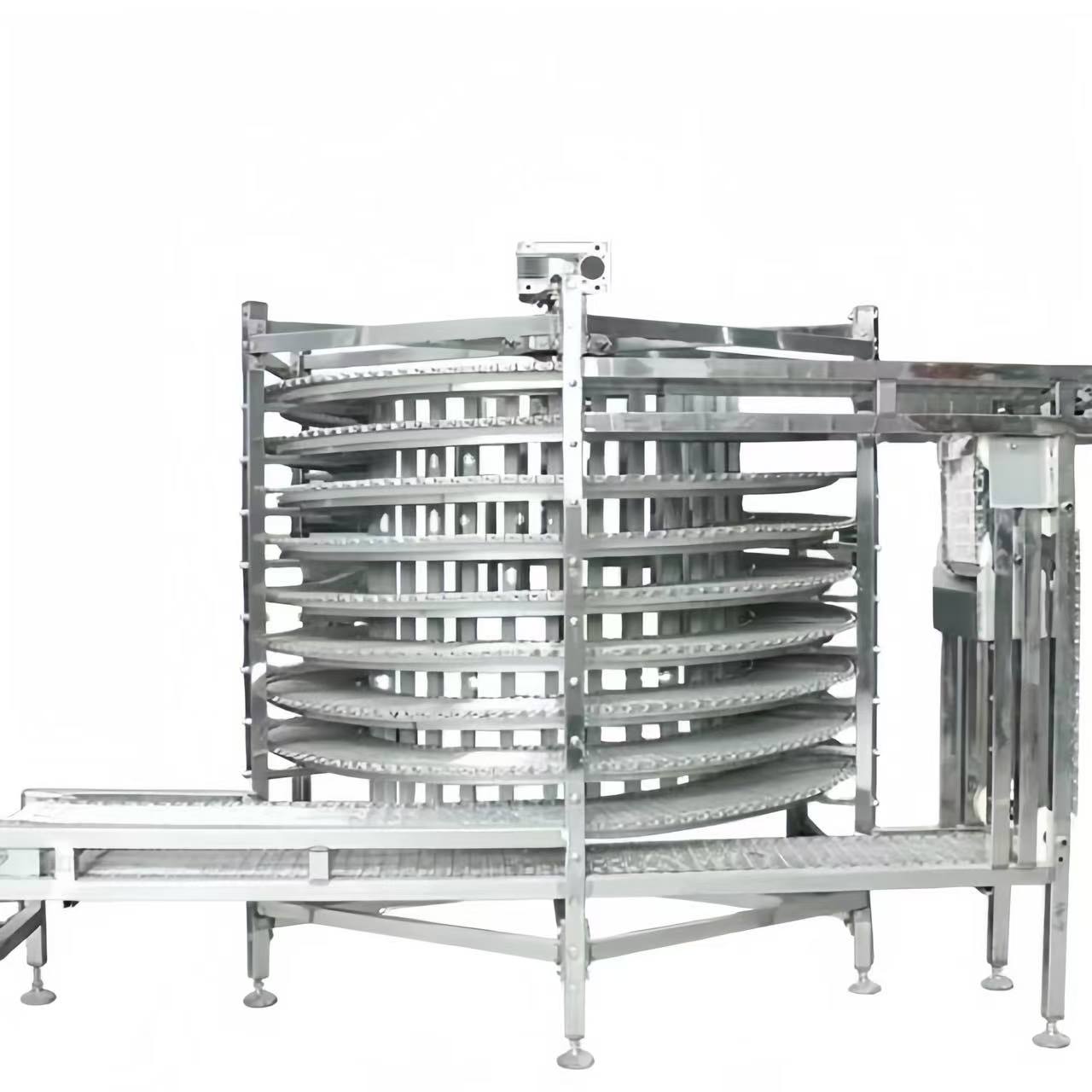

Spiral Conveyor Buffer Cooling Tower Flexible Spiral Conveyor Chain System for Food Industry

Product Case

Application scenarios

1. Spiral conveyors are an effective way to transport products, items, or boxes between floors. They are sometimes called corkscrew conveyors or vertical conveyors as they use a conveyor belt to take the items up and down between levels.

2. Spiral and buffer cooling tower are used in the delivery while cooling, freezing and preservation, Besides, the spiral conveyor is the ideal solution for vertical delivery, which minimize the room.

3. With the advantages of low friction, our flexible chains and modular belts don’t need to be lubricated, which can prevent the products from pollution. Which widely used in food industry.

4. Ideally suited for the beverage, glass, food, pharmaceutical and paint industries.

5. Flexible screw conveyor has become an important transport equipment in the whole production link in the industries of beverage, beer, post, newspaper, printing, food, pharmaceutical, logistics, electronics and other enterprises,. Also applicable to electronic appliances, home appliance manufacturers, auto parts, motorcycles, food and medicine, postal, airport, logistics distribution and distribution center and many other industries.

Product parameters

| Modes | Characteristics |

| Plastic chain type | Conveyor frame:SS304/Carbon steel Belt:SS304/carbon steel base chain+plastic chain( CSTANS 1873 series) Belt Width:304.8mm/406mm/457.2mm Height:Customized Application: Food&beverage industry, Logistic industry,Packaging&Cans etc. |

| Modular Belt Type | Conveyor frame:SS304 Belt material:Plastic ( 7100 series) Belt width:350-800mm Dimension:Customized Application: Food industry |

| Roller Type | Conveyor frame: SS304 Belt: Roller Belt width:300-800mm Dimension:Customized Application:Food&beverage industry,Logistics industry,Packaging & Cans.etc. |

Product advantages

(1). Natural cooling keep the bread's natural taste and aroma.

(2). Framework is high quality stainless steel, ensure stability of spiral cooling tower.

(3). The conveying belt with mesh is made of high strength stainless steel.

(4). Internal structure of spiral cooling tower is more convenient to servicing.

(5). Spiral cooling tower entry/exit configuration options permit most efficient use of available plant space.

(6). Installation of spiral conveyor has enough flexibility, it possible to configure plant of any kind and for any type of

need, that are perfectly adaptable to any already existent production line.

(7). Cleaning job made simple. The conveyor belt made entirely out of stainless steel and the special constructional

system, that allows the user to reach easily every part of the spiral, make it possible to achieve the high hygiene and health

standards required by the food industry