sprocket

basic info

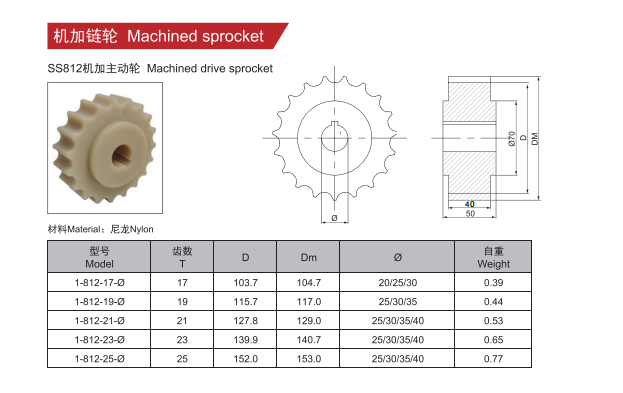

| <!-- x-tinymce/html -->Model NO. | <!-- x-tinymce/html -->sprocket | <!-- x-tinymce/html -->Type | <!-- x-tinymce/html -->sprocket |

| <!-- x-tinymce/html -->Material | <!-- x-tinymce/html -->Plastic | <!-- x-tinymce/html -->Inside Material | <!-- x-tinymce/html -->Nylon |

| <!-- x-tinymce/html -->Feature | <!-- x-tinymce/html -->Wear-Resistant | <!-- x-tinymce/html -->Tensile Strength | <!-- x-tinymce/html -->Common |

| <!-- x-tinymce/html -->Width | Based on the number of teeth | <!-- x-tinymce/html -->Trademark | <!-- x-tinymce/html -->WA |

| <!-- x-tinymce/html -->Specification | sprocket | <!-- x-tinymce/html -->Origin | <!-- x-tinymce/html -->Shandong |

Stainless steel turning chain plate with matching sprocket

Structural Design

Gear design: The gear teeth of the sprocket have been precisely processed. The pitch and tooth height are perfectly matched with the dimensions of the stainless steel turning chain plate link, ensuring precise meshing between the chain plate and the sprocket, thereby reducing impact and wear during the transmission process. The gear teeth of the turning sprocket will be specially optimized according to the turning angle (such as 90°, 180°), with the tooth surface curvature matching the turning trajectory of the chain plate, ensuring a smooth transition of the chain plate during turning and avoiding chain jamming or deviation.

Performance Characteristics

High transmission efficiency: The precise tooth design and excellent meshing performance enable the sprocket to efficiently transfer power, reduce energy loss, and ensure the stable speed of the chain plate conveyor.

High wear resistance: The stainless steel material itself has high hardness, combined with precise processing technology, the tooth surface of the sprocket has excellent wear resistance, which can withstand the meshing friction of the chain plate for a long time and extend the service life.

Smooth operation: The special structure design at the turning points ensures that the chain plate maintains stable contact with the sprocket during the turning process, resulting in smooth transmission without noise and avoiding the spillage of materials due to vibration.

Easy maintenance: The stainless steel material is not prone to accumulation of dirt and has a smooth surface, making it easy for daily cleaning and disinfection; the structure is simple, the components have strong interchangeability, and replacement and maintenance are convenient.

The matching sprocket needs to be strictly compatible with the model and specification of the stainless steel turning chain plate (such as the width of the chain plate and the pitch of the links). Different chain plate parameters correspond to different sizes of sprockets. The manufacturer can customize the diameter, number of teeth, material and structure of the sprocket according to the specific requirements of the conveying system, such as the turning angle, load-bearing capacity and running speed, to ensure the best fit with the chain plate and meet the requirements of personalized conveying scenarios.